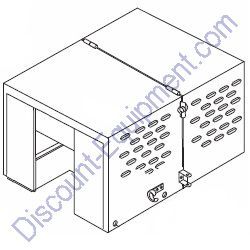

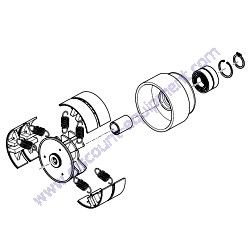

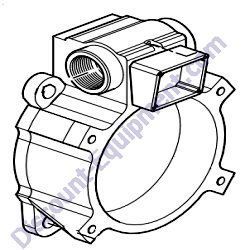

Multiquip DIS185SSI4FS Air Compressor 185CFM Skid Mount with Isuzu 4LE2T Diesel Engine Tier 4 Final

Safety Information

Multiquip DIS185SSI4F Air Compressor

SAFETY INFORMATION

GENERAL SAFETY

CAUTION

„ NEVER operate this equipment without proper protective clothing, shatterproof glasses, respiratory protection, hearing protection, steel-toed boots and other protective devices required by the job or city and state regulations.

„ NEVER operate this equipment when not feeling well due to fatigue, illness or when under medication.

„ NEVER operate this equipment under the influence of drugs or alcohol.

„ ALWAYS check the equipment for loosened threads or bolts before starting.

„ DO NOT use the equipment for any purpose other than its intended purposes or applications.

NOTICE

„ This equipment should only be operated by trained and qualified personnel 18 years of age and older.

„Whenever necessary, replace nameplate, operation and safety decals when they become difficult read.

„ Manufacturer does not assume responsibility for any accident due to equipment modifications. Unauthorized equipment modification will void all warranties

„ NEVER use accessories or attachments that are not recommended by MQ Power for this equipment. Damage to the equipment and/or injury to user may result.

„ ALWAYS know the location of the nearest fire extinguisher.

„ ALWAYS know the location of the nearest first aid kit.

„ ALWAYS know the location of the nearest phone or keep a phone on the job site. Also, know the phone numbers of the nearest ambulance, doctor and fire department.

This information will be invaluable in the case of an emergency.

AIR COMPRESSOR SAFETY

DANGER

„ NEVER operate the equipment in an explosive atmosphere or near combustible materials. An explosion or fi re could result causing severe bodily harm or even death.

„ Keep the towing vehicle or equipment carrier, compressor hoses, tools, and all personnel at least 10 feet (3 m) from power lines and buried cables.

„ DO NOT use air from this air compressor for respiration (breathing).

„ Stay clear of the compressor during electrical storms! It can attract lightning.

„ DO NOT engage in horseplay with air hoses as death or serious injury may result.

„ NEVER use air compressor for respirator equipment by which compressed air is supplied for human consumption. The compressed air contains carbon monoxide and other contaminants. Such air may cause serious injury or death if used by a person for respiration.

„ This compressor is not designed for air pressurized construction methods and underwater diving jobs

„ NEVER use compressed air for human consumption such as pressurizing diving air tanks. Consumption of compressed air can cause death while diving.

WARNING

„ NEVER disconnect any emergency or safety devices.

These devices are intended for operator safety.

Disconnection of these devices can cause severe injury, bodily harm or even death. Disconnection of any of these devices will void all warranties.

„ If air compressor is operated indoors, discharge engine exhaust fumes outdoors.

„ Locate the air compressor so that exhaust fumes are not apt to be carried towards personnel.

„ NEVER blow compressed air directly at people. Scattered dust, or foreign debris in the compressed air may cause serious injuries.

„ Blowing compressed air on food is prohibited.

„ NEVER, under any circumstances, open the oil filler cap on oil chamber tank while air compressor is running or immediately after stopping operation. It is very dangerous and may cause serious injury.

„ Residual air pressure can cause severe bodily injury.

„ Residual air pressure in the oil chamber tank could force both extremely hot compressed air and oil to jet out causing scalding or severe bodily harm.

CAUTION

„ NEVER lubricate components or attempt service on a running machine.

„ Fuels, fluids, coolants, lubricants, and battery electrolyte used in the air compressor are typical of the industry.

Care should be taken to avoid accidental ingestions and/ or skin contact

„ Keep personnel away from the discharge opening of hoses, tools or other points of compressed air.

NOTICE

„ ALWAYS ensure air compressor is on level ground before use.

„ ALWAYS keep the machine in proper running condition.

„ Fix damage to machine and replace any broken parts immediately.

„ NEVER operate the air compressor with the service valves open unless air hoses and/or pipes are connected.

„ ALWAYS store equipment properly when it is not being used. Equipment should be stored in a clean, dry location out of the reach of children and unauthorized personnel

„ DO NOT use pneumatic air tools that are rated above the maximum psi rating of the compressor.

„ Select tools, air hoses, pipes, valves, filters and other fittings accordingly. DO NOT exceed the manufacturer's rated safe operating pressures for these items.

„ DO NOT use air to pressures higher than 30 psi (207 kPa, 2.1 kgf/cm2 ) for cleaning purposes.

„When refilling the oil chamber tank with oil, stop the engine, and make sure that the pressure gauge indicates zero psi, and that there is no residual pressure. Then gradually loosen the oil filler cap .

„ Make sure the air pressure reads zero before performing any maintenance.

„When removing dust and debris that have accumulated in such devices such as air filters, by blowing compressed air, wear safety glasses, etc. to protect eyes.

„When the air compressor has to be unavoidably operated (temporarily) with its port open, be sure to mount a silencer to reduce noise and wear protective materials such as earplugs to prevent damage to hearing. For service testing only.

ENGINE SAFETY

DANGER

„ The engine fuel exhaust gases contain poisonous carbon monoxide. This gas is colorless and odorless, and can cause death if inhaled.

„ The engine of this equipment requires an adequate free flow of cooling air. NEVER operate this equipment in any enclosed or narrow area where free flow of the air is restricted. If the air flow is restricted it will cause injury to people and property and serious damage to the equipment or engine.

WARNING

„ DO NOT place hands or fingers inside engine compartment when engine is running.

„ NEVER operate the engine with heat shields or guards removed.

„ Keep fingers, hands hair and clothing away from all moving parts to prevent injury.

„ DO NOT remove the radiator cap while the engine is hot. High pressure boiling water will gush out of the radiator and severely scald any persons in the general area of the generator.

„ DO NOT remove the coolant drain plug while the engine is hot. Hot coolant will gush out of the coolant tank and severely scald any persons in the general area of the generator

.

„ DO NOT remove the engine oil drain plug while the engine is hot. Hot oil will gush out of the oil tank and severely scald any persons in the general area of the

generator.

CAUTION

„ NEVER touch the hot exhaust manifold, muffler or cylinder. Allow these parts to cool before servicing equipment.

NOTICE

„ NEVER run engine without an air filter or with a dirty air filter. Severe engine damage may occur. Service air filter frequently to prevent engine malfunction.

„ NEVER tamper with the factory settings of the engine or engine governor. Damage

to the engine or equipment can result if operating in speed ranges above the

maximum allowable.

„Wet stacking is a common problem with diesel engines which are operated for extended periods with light or no load applied. When a diesel engine operates without sufficient load (less than 40% of the rated output), it will not operate at its optimum temperature. This will allow unburned fuel to accumulate in the exhaust system, which can foul the fuel injectors, engine valves and exhaust system, including turbochargers, and reduce the operating performance.

In order for a diesel engine to operate at peak efficiency, it must be able to provide fuel and air in the proper ratio and at a high enough engine temperature for the engine to completely burn all of the fuel.

Wet stacking does not usually cause any permanent damage and can be alleviated if additional load is applied to relieve the condition. It can reduce the system performance and increase maintenance. Applying an increasing load over a period of time until the excess fuel is burned off and the system capacity is reached

usually can repair the condition. This can take several hours to burn off the accumulated unburned fuel.

„ State Health Safety Codes and Public Resources Codes specify that in certain locations, spark arresters must be used on internal combustion engines that use

hydrocarbon fuels. A spark arrester is a device designed to prevent accidental discharge of sparks or flames from the engine exhaust. Spark arresters are qualified and rated by the United States Forest Service for this purpose. In order to comply with local laws regarding spark arresters, consult the engine distributor or the local Health and Safety Administrator.

FUEL SAFETY

DANGER

„ DO NOT start the engine near spilled fuel or combustible fluids. Diesel fuel is extremely flammable and its vapors can cause an explosion if ignited.

„ ALWAYS refuel in a well-ventilated area, away from sparks and open flames.

„ ALWAYS use extreme caution when working with flammable liquids.

„ DO NOT fill the fuel tank while the engine is running or hot.

„ DO NOT overfill tank, since spilled fuel could ignite if it comes into contact with hot engine parts or sparks from the ignition system.

„ Store fuel in appropriate containers, in well-ventilated areas and away from sparks and flames.

„ NEVER use fuel as a cleaning agent.

„ DO NOT smoke around or near the equipment. Fire or explosion could result

from fuel vapors or if fuel is spilled on a hot engine.

TOWING SAFETY

CAUTION

„ Check with your local county or state safety towing regulations, in addition to meeting Department of Transportation (DOT) Safety Towing Regulations, before towing

your generator.

„ Refer to MQ Power trailer manual for additional safety information.

„ In order to reduce the possibility of an accident while transporting the generator on public roads, ALWAYS make sure the trailer that supports the generator and the towing vehicle are mechanically sound and in good operating condition.

„ ALWAYS shutdown engine before transporting

Make sure the hitch and coupling of the towing vehicle are rated equal to, or greater than the trailer “gross vehicle weight rating.”

„ ALWAYS inspect the hitch and coupling for wear. NEVER tow a trailer with defective hitches, couplings, chains, etc.

„ Check the tire air pressure on both towing vehicle and trailer. Trailer tires should be inflated to 50 psi cold. Also check the tire tread wear on both vehicles.

„ ALWAYS make sure the trailer is equipped with a safety chain.

„ ALWAYS properly attach trailer’s safety chains to towing vehicle.

„ ALWAYS make sure the vehicle and trailer directional, backup, brake and trailer lights are connected and working properly.

„ DOT Requirements include the following:

• Connect and test electric brake operation.

• Secure portable power cables in cable tray with tie wraps.

„ The maximum speed for highway towing is 55 MPH unless posted otherwise. Recommended off-road towing is not to exceed 15 MPH or less depending on type of terrain.

„ Avoid sudden stops and starts. This can cause skidding, or jack-knifing. Smooth, gradual starts and stops will improve towing.

„ Avoid sharp turns to prevent rolling.

„ Trailer should be adjusted to a level position at all times when towing.

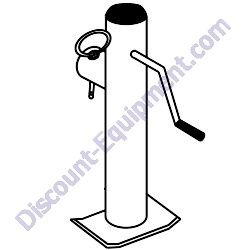

„ Raise and lock trailer wheel stand in up position when towing.

„ Place chock blocks underneath wheel to prevent rolling while parked.

„ Place support blocks underneath the trailer’s bumper to prevent tipping while parked.

„ Use the trailer’s swivel jack to adjust the trailer height to a level position while parked.

BATTERY SAFETY

DANGER

„ DO NOT drop the battery. There is a possibility that the battery will explode.

„ DO NOT expose the battery to open flames, sparks, cigarettes, etc. The battery contains combustible gases and liquids. If these gases and liquids come into contact with a flame or spark, an explosion could occur.

WARNING

„ ALWAYS wear safety glasses when handling the battery to avoid eye irritation.

The battery contains acids that can cause injury to the eyes and skin.

„ Use well-insulated gloves when picking up the battery.

„ ALWAYS keep the battery charged. If the battery is not charged, combustible gas will build up.

„ ALWAYS recharge the battery in a well-ventilated environment to avoid the risk of a dangerous concentration of combustible gasses.

„ If the battery liquid (dilute sulfuric acid) comes into contact with clothing or skin, rinse skin or clothing immediately with plenty of water.

„ If the battery liquid (dilute sulfuric acid) comes into contact with eyes, rinse eyes immediately with plenty of water and contact the nearest doctor or hospital to

seek medical attention.

CAUTION

„ ALWAYS disconnect the NEGATIVE battery terminal before performing service on the generator.

„ ALWAYS keep battery cables in good working condition.

Repair or replace all worn cables.

ENVIRONMENTAL SAFETY/DECOMMISSIONING

NOTICE

Decommissioning is a controlled process used to safely retire a piece of equipment that is no longer serviceable.

If the equipment poses an unacceptable and unrepairable safety risk due to wear or damage or is no longer cost effective to maintain (beyond life-cycle reliability) and is to be decommissioned (demolition and dismantlement),be sure to follow rules below.

„ DO NOT pour waste or oil directly onto the ground, down a drain or into any water source.

„ Contact your country's Department of Public Works or recycling agency in your

area and arrange for proper disposal of any electrical components, waste or oil

associated with this equipment.

„When the life cycle of this equipment is over, remove battery and bring to appropriate facility for lead reclamation. Use safety precautions when handling

batteries that contain sulfuric acid.

„When the life cycle of this equipment is over, it is recommended that the trowel frame and all other metal parts be sent to a recycling center.

Metal recycling involves the collection of metal from discarded products and its transformation into raw materials to use in manufacturing a new product.

Recyclers and manufacturers alike promote the process of recycling metal. Using a metal recycling center promotes energy cost savings.

EMISSIONS INFORMATION

NOTICE

The diesel engine used in this equipment has been designed to reduce harmful levels of carbon monoxide (CO), hydrocarbons (HC) and nitrogen oxides (NOx) contained in diesel exhaust emissions.

This engine has been certified to meet US EPA Evaporative emissions requirements in the installed configuration.

Attempting to modify or make adjustments to the engine emission system by unauthorized personnel without proper training could damage the equipment or create an unsafe

condition.

Additionally, modifying the fuel system may adversely affect evaporative emissions, resulting in fines or other penalties.

Emission Control Label

The emission control label is an integral part of the emission system and is strictly controlled by regulations.

The label must remain with the engine for its entire life.

If a replacement emission label is needed, please contact your authorized engine distributor. |